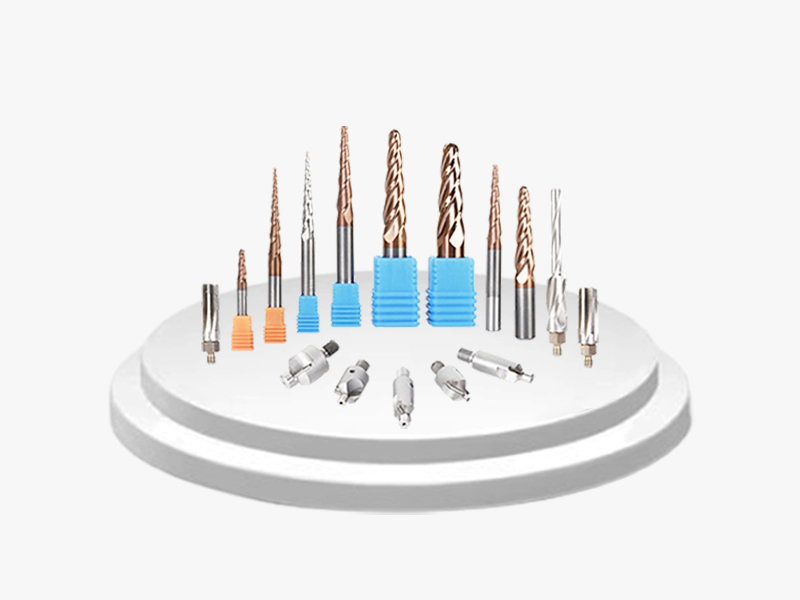

The threaded shank reamer is a cutting tool specially designed to enlarge the hole diameter. Its unique threaded shank design allows it to maintain stability and efficiency during the machining process. This reamer is made of high-quality materials and undergoes precision machining and heat treatment to ensure excellent cutting performance and durability.

The threaded shank of the threaded shank reamer drill is tightly and firmly connected to the machine tool spindle, which can effectively prevent shaking or deflection during processing, thereby ensuring processing accuracy and stability. At the same time, the cutting part of the reamer adopts a unique geometric design, which can quickly and accurately expand the hole diameter to achieve ideal processing results.

During use, the threaded shank reamer demonstrates excellent cutting performance and stability. It can easily cope with the processing needs of various materials, whether metal, non-metal or composite materials, and can achieve efficient and precise hole expansion operations. In addition, the durability of the reamer is also very good. Even during long-term and high-intensity machining, it can maintain stable cutting performance and extend its service life.

The threaded shank reamer is also easy to operate. It adopts a standardized interface design to facilitate users to quickly install and replace tools. At the same time, the maintenance of the reamer is relatively simple. Users can clean and lubricate it as needed to ensure the good operating condition of the tool.

The threaded shank reamer is a cutting tool with high performance, high precision and high stability. It can help users achieve efficient and precise hole expansion processing and improve product quality and production efficiency. Whether used in machinery manufacturing, automobile repair, aerospace and other fields, threaded shank reamers can exert their excellent performance and advantages.

lubin@china-end-mill.com

lubin@china-end-mill.com