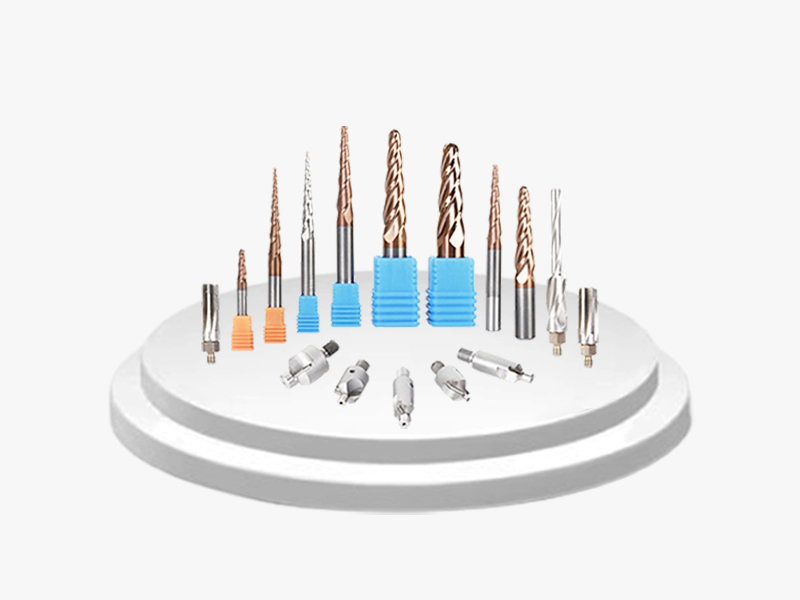

● Excellent cutting performance

Steel drill bits are optimized for the high hardness and toughness of steel and have excellent cutting performance. Its sharp cutting edge and reasonable geometric angle can quickly cut into steel, reduce cutting resistance, and increase drilling speed and processing efficiency. Whether it is thin sheet steel or thick-walled steel pipes, steel drills can demonstrate excellent cutting results.

● Excellent wear resistance and durability

Steel drill bits are made of high-quality wear-resistant materials and undergo precise heat treatment and coating to provide excellent wear resistance and durability. When machining steel, the drill retains a sharp cutting edge for a long time, reducing the risk of wear and damage and extending its service life. This enables steel drill bits to cope with long-term, high-load drilling operations, reduce the frequency of drill bit replacement, and improve production efficiency.

● High-precision drilling effect

Steel drill bits are precision manufactured and calibrated to ensure high-precision drilling results. Its design takes into account the cutting characteristics and thermal deformation characteristics of steel, effectively reducing deviations and vibrations during the drilling process and ensuring the accuracy and consistency of hole positions. This makes steel drill bits have wide application value in precision manufacturing, mechanical processing and other fields.

● Good chip removal and heat dissipation performance

The design of steel drill bits focuses on chip removal and heat dissipation performance. By optimizing the drill bit's groove shape and chip removal structure, it ensures that chips can be discharged smoothly and reduces chip clogging and the accumulation of cutting heat. At the same time, the steel drill bit is made of high-quality materials and has good thermal conductivity, which can dissipate cutting heat in time and maintain the stable cutting state of the drill bit.

● Easy to install and operate

The drill bit for steel is reasonably designed, easy to install and easy to operate. Its standardized interface and adaptability make it easy to use with a variety of drilling machines and machining equipment. In addition, the operation process of steel drill bits is stable and reliable, reducing operating difficulty and human errors, and improving work efficiency and processing quality.

lubin@china-end-mill.com

lubin@china-end-mill.com