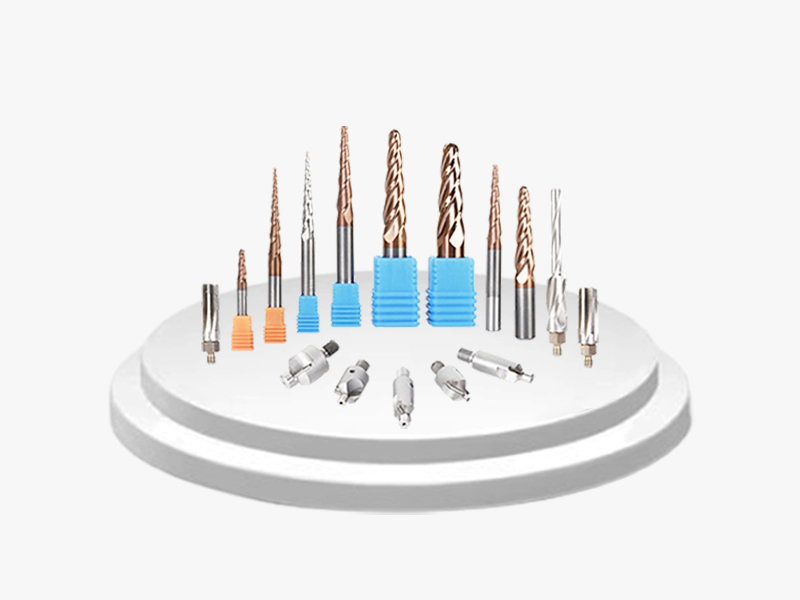

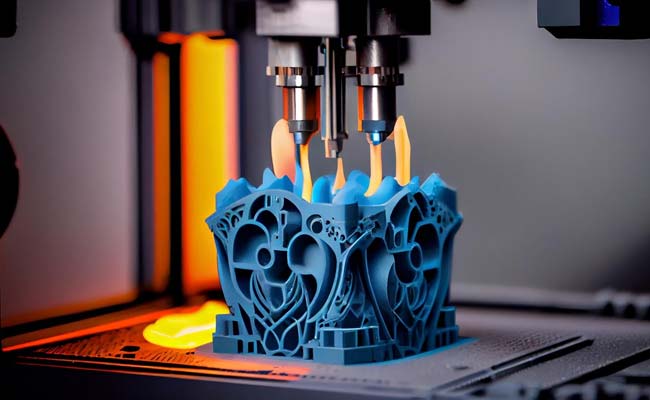

● Improve cutting efficiency:

The coating material on the surface of the coated milling cutter can reduce the friction coefficient during cutting, reduce cutting force, and make the cutting process smoother. This can not only increase the cutting speed, but also reduce the energy loss during the cutting process and significantly improve the processing efficiency.

● Enhanced tool life:

The coating material has good wear resistance and corrosion resistance, and can effectively protect the milling cutter matrix and reduce tool wear and corrosion. Therefore, coated milling cutters can maintain a longer service life during use, reduce the frequency of tool replacement, and reduce production costs.

● Improve cutting quality:

Coated milling cutters can reduce cutting temperatures, reduce thermal deformation and residual stress during cutting, thereby improving the surface quality and accuracy of the workpiece. In addition, the coating can reduce vibration and noise during cutting, further improving cutting stability.

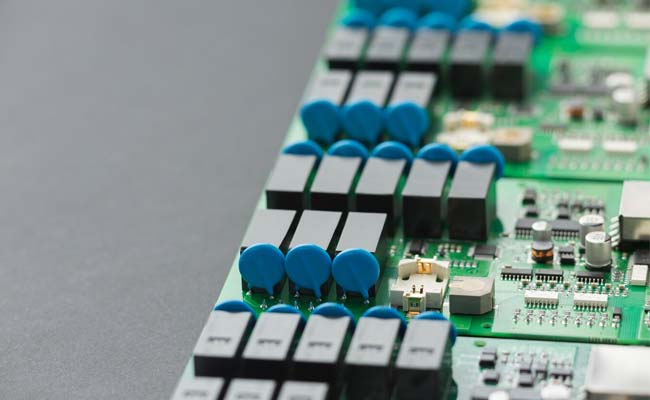

● Expand application scope:

Coated milling cutters are suitable for a variety of materials and machining scenarios. Different coating materials and processes can be optimized for specific materials and processing needs, allowing coated milling cutters to maintain good cutting performance when processing materials of different hardnesses.

● Environmental protection and sustainability:

The coating materials used in coated milling cutters usually have good environmental performance and do not contain harmful substances. At the same time, the application of coating technology also helps reduce material waste and energy consumption during the cutting process, which is in line with the development trend of green manufacturing.

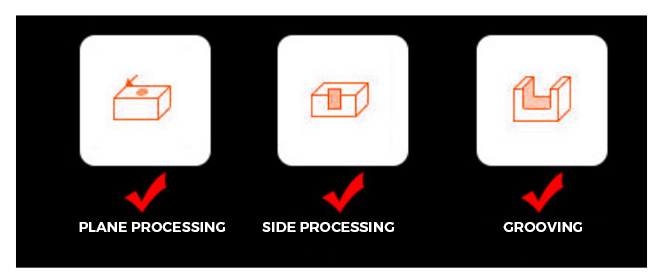

SUITABLE FOR PROCESSING

lubin@china-end-mill.com

lubin@china-end-mill.com