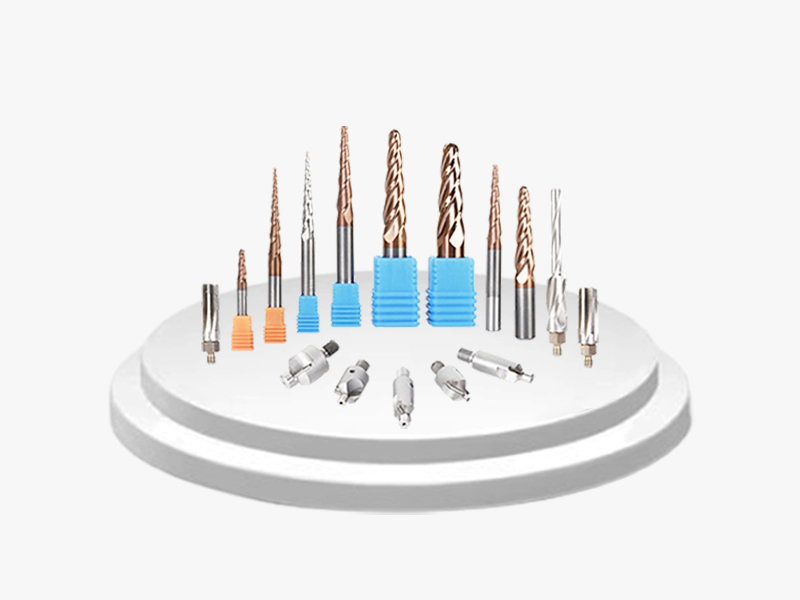

The threaded shank drill bit is a cutting tool designed for efficient and precise drilling operations. It is widely praised in the field of machining for its unique threaded shank design and excellent performance.

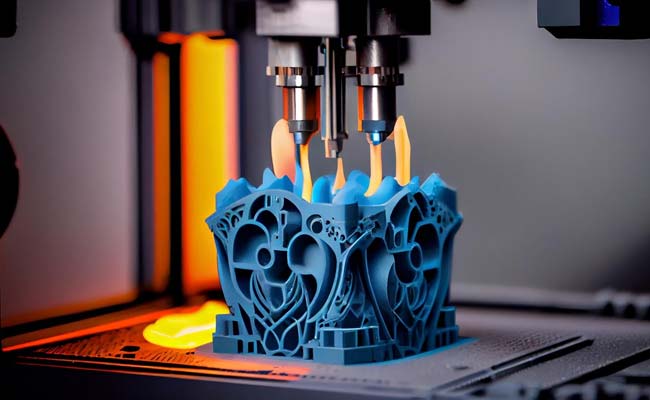

This drill bit is made of high-strength, high-wear-resistant materials and undergoes precise processing and heat treatment to ensure its stability and durability in various working environments. Its unique threaded shank design makes the connection between the drill bit and the machine tool spindle tighter and more reliable, effectively reducing vibration and deviation and improving drilling accuracy.

The cutting part of the threaded shank drill adopts advanced geometric shape design, which can quickly cut into the workpiece, reduce cutting resistance, and improve drilling efficiency. At the same time, the sharp cutting edge of the drill can quickly remove material from the workpiece, achieving smooth and precise hole wall processing. Whether it's hard metal, composites or other materials, threaded shank drills handle it with ease and deliver outstanding cutting performance.

The threaded shank drill bit also has excellent heat dissipation performance, which can effectively reduce the heat generated during the cutting process, reduce tool wear, and extend service life. At the same time, its compact structure and light weight make it easy for users to operate and carry.

The threaded shank drill bit is a cutting tool that combines efficiency, precision, stability and durability. It can meet various drilling needs and is widely used in machinery manufacturing, automobile maintenance, aerospace and other fields. Whether it is mass production or fine processing, threaded shank drill bits can exert their excellent performance and advantages to help users achieve high-quality drilling operations.

lubin@china-end-mill.com

lubin@china-end-mill.com