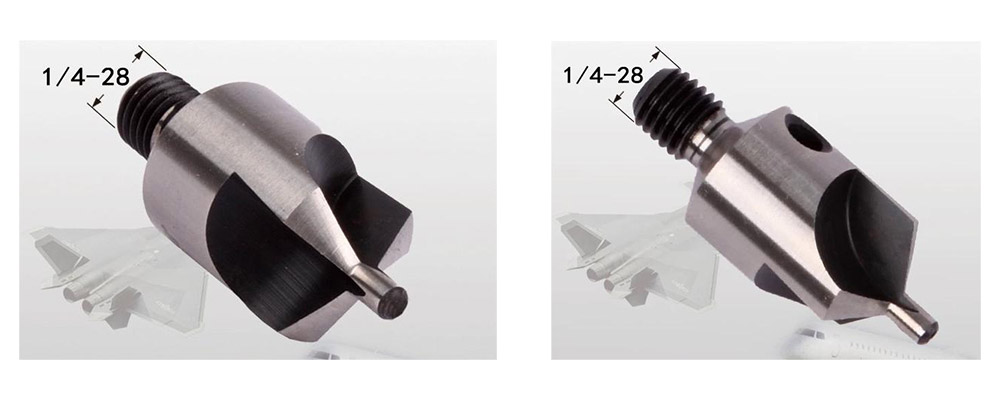

The high-speed steel countersink drill is a high-performance tool designed for efficient cutting and precision machining. It is made of high-quality high-speed steel material, which combines high hardness, high wear resistance and good thermal stability, allowing the countersink drill to maintain excellent cutting performance and stability during high-speed cutting.

Its design has been carefully optimized, and the cutting edge part has been specially treated to ensure that it can remain sharp during high-speed rotation and cutting, reduce cutting force, and reduce cutting heat, thereby achieving an efficient and smooth cutting process. In addition, its sturdy structure can maintain stable cutting performance under high-load working conditions, effectively extending the service life of the tool.

This countersink drill demonstrates extremely high precision and reliability during machining. Whether it is rough machining or finishing machining of metal materials, it can accurately control the cutting depth and cutting speed to ensure that the processed holes are accurate in size and have excellent surface quality. At the same time, high-speed steel countersink drills also have good thermal stability and wear resistance, which can maintain stable cutting performance and improve processing efficiency during long-term continuous work.

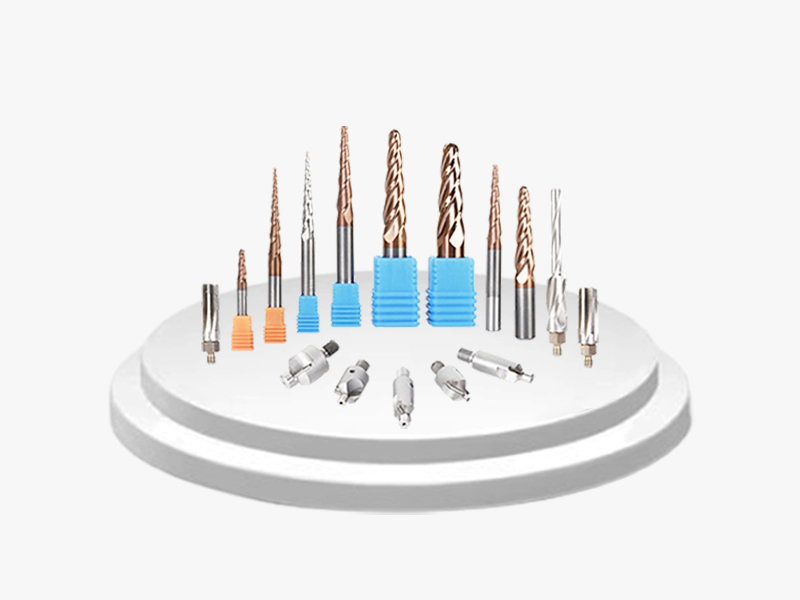

The wide application range of high-speed steel countersink drills is also a major advantage. It is suitable for various mechanical processing fields, including aerospace, automobile manufacturing, mold processing, etc., and can meet different industries and different processing needs. Whether it is processing large workpieces or small parts, high-speed steel countersink drills can exert excellent cutting performance and bring higher efficiency and quality to processing and production.

The high-speed steel countersink drill is an efficient, precise, reliable and widely applicable cutting tool. With its excellent performance and wide range of applications, it has become one of the indispensable and important tools in the field of mechanical processing.

lubin@china-end-mill.com

lubin@china-end-mill.com