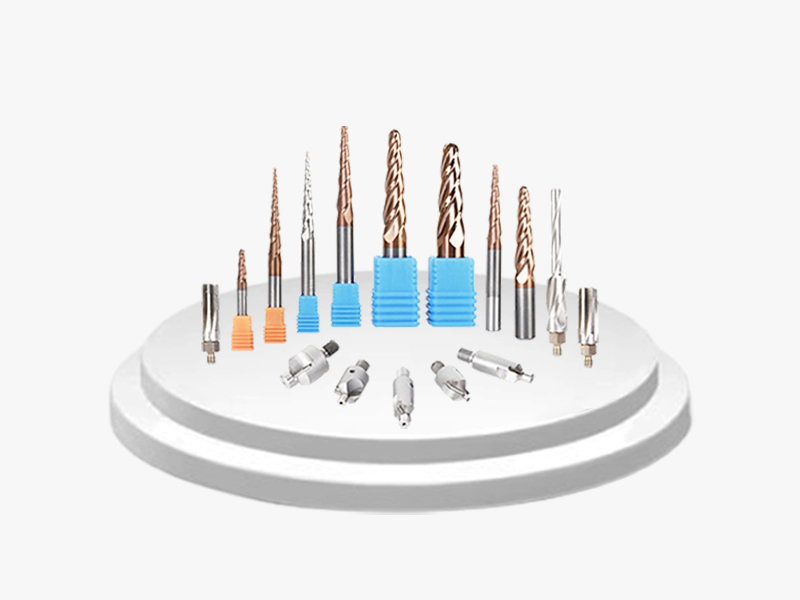

Taper milling cutter, as a professional cutting tool, is widely used in machinery manufacturing, mold processing, aerospace and other fields. Its unique taper design makes it easy to process irregular shapes such as cones and bevels, greatly improving processing efficiency and accuracy.

● Product features

High-quality materials: The taper milling cutter is made of alloy steel with high hardness and high wear resistance. It undergoes a precise heat treatment process to ensure the strength and toughness of the cutter and extend its service life.

Precise taper: The taper design of the tool has been strictly calculated and tested to ensure stability and accuracy during the machining process. Whether it is a large taper or a small taper, high-precision machining can be easily achieved.

Efficient cutting: The taper milling cutter adopts optimized cutting angle and edge design, which reduces cutting force, increases cutting speed, effectively reduces heat generation during processing, and ensures the processing quality of the workpiece.

Wide scope of application: Taper milling cutters are suitable for processing various materials, including metals, non-metals, etc., and can meet the processing needs of different industries.

● How to use

Installation: Install the taper milling cutter on the tool holder of the milling machine or CNC machine tool, ensuring that the installation is firm to avoid loosening during processing.

Debugging: According to the processing requirements, adjust the cutting depth, feed speed and other parameters of the tool to ensure the stability and safety of the processing process.

Processing: Start the equipment and make the taper milling cutter perform cutting according to the preset trajectory. Pay attention to the cutting situation during the processing and adjust the parameters in time to ensure the processing quality.

● Maintenance

Regular inspection: Regularly check the wear of the taper milling cutter. If serious edge wear or other damage is found, the tool should be replaced in time.

Cleaning and maintenance: After use, clean the chips and oil on the surface of the tool in time to keep the tool clean and dry to prevent rust and corrosion.

Storage precautions: Store the taper milling cutter in a dry, ventilated place away from direct sunlight and moisture to ensure long-term use of the cutter.

lubin@china-end-mill.com

lubin@china-end-mill.com