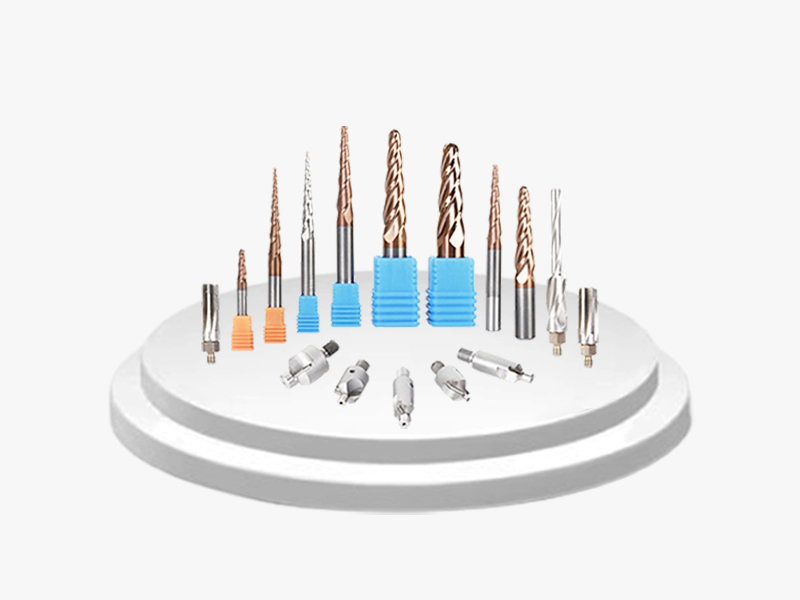

Wave edge milling cutter, tungsten steel wave edge milling cutter, solid tungsten steel milling cutter, corrugated milling cutter: Corrugated milling cutter, also known as rough skin milling cutter, is a rotating tool with one or more teeth used for rough milling.

The helix angle is 30°, and the coatings include TICN coating, TIN coating, TIALN nano super-hard coating and non-coating. It has good chip removal performance and large chip removal volume. Has high metal removal rate.

Applicable to: stainless steel, aluminum alloy, mold steel, tool steel, carbon steel, alloy steel, cast iron, general iron materials, etc. Mostly used for groove processing and step surface processing.

The groove of the corrugated milling cutter is fully ground, smooth, has good chip removal performance, high hardness and high precision.

lubin@china-end-mill.com

lubin@china-end-mill.com