● Highly customized to meet individual needs

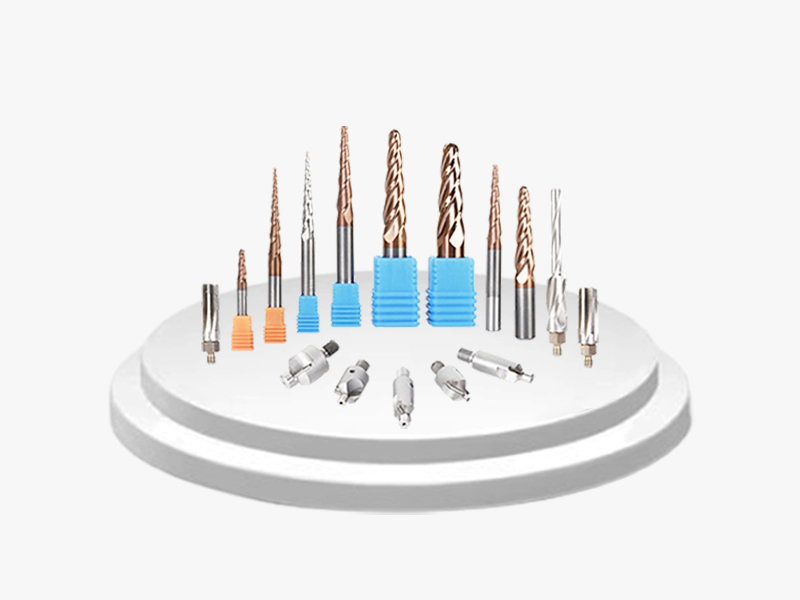

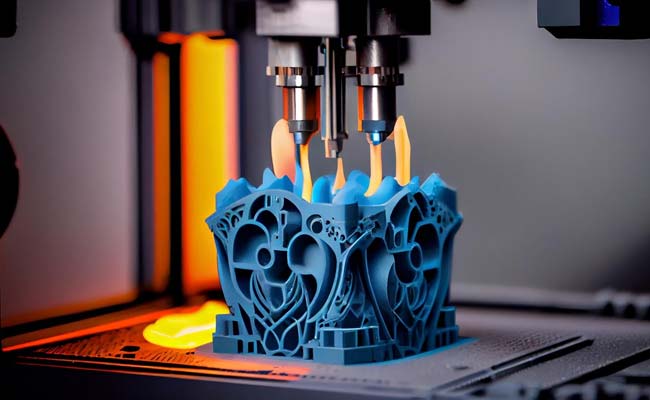

Non-standard indexable tools are highly customized for customers' specific processing needs and workpiece characteristics. Whether it is the shape, size or cutting parameters of the tool, they can be accurately designed and manufactured according to customer needs. This highly customized feature allows non-standard indexable tools to perfectly match various complex workpieces and special processing scenarios, achieving efficient and precise cutting.

● Indexable design to improve flexibility and adaptability

Non-standard indexable tools adopt a unique indexable design, which allows quick and easy index adjustment during use. This design allows the tool to flexibly respond to different processing needs. Whether it is changing the cutting angle, adjusting the cutting depth, or adapting to the cutting characteristics of different materials, it can be easily achieved through a simple indexing operation. This high degree of flexibility and adaptability makes non-standard indexable tools have broad application prospects in complex and changeable processing environments.

● Excellent cutting performance, improve processing efficiency

Non-standard indexable tools use high-quality materials and advanced manufacturing processes to provide excellent cutting performance. Its sharp cutting edge and reasonable geometric angle design can reduce cutting resistance and increase cutting speed, thereby achieving efficient processing. At the same time, non-standard indexable tools have good cutting stability and can maintain stable cutting conditions for a long time, reduce tool wear and replacement frequency, and further improve processing efficiency.

● Sturdy and durable, reducing maintenance costs

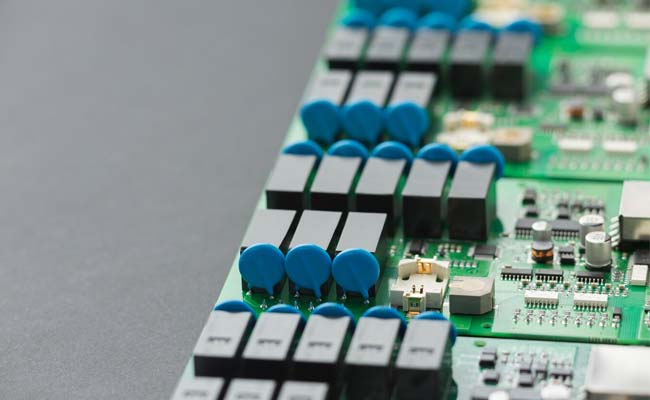

Non-standard indexable tools are made of wear-resistant and high-temperature-resistant materials, and undergo precise heat treatment and coating to provide excellent durability and stability. In long-term, high-load cutting operations, non-standard indexable tools can maintain stable cutting performance and are not prone to wear and damage. This reduces the frequency of tool changes and maintenance costs, saving customers a lot of time and money.

● Easy to operate and improve work efficiency

Non-standard indexable tools are reasonably designed, easy to install and easy to operate. Its standardized interface and adaptability make it easy to use with a variety of cutting equipment and machining systems. At the same time, the indexing adjustment process of non-standard indexable tools is simple and fast, without complex operations and adjustments, reducing operating difficulty and human errors, and improving work efficiency and processing quality.

lubin@china-end-mill.com

lubin@china-end-mill.com