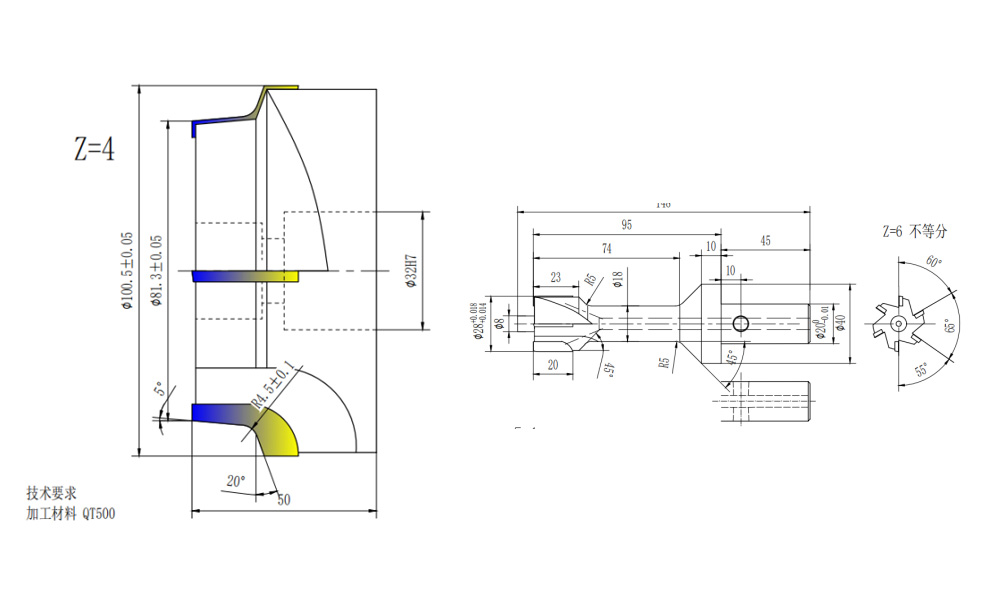

● Customized design to meet diverse needs

Non-standard welding tools are customized and designed according to the specific needs of customers and the characteristics of the welding process to ensure that the tools can perfectly match the welding materials and process requirements. Whether it is the shape and size of the tool or the location and number of welding points, it can be accurately adjusted according to customer needs to achieve personalized customization and meet diverse needs.

● Efficient welding performance and improved production efficiency

Non-standard welding tools use advanced welding technology and cutting technology to maintain stable welding quality and efficient welding speed during the welding process. Its excellent cutting performance and precise welding control make the welding process smoother and more efficient, greatly improving production efficiency and shortening the production cycle.

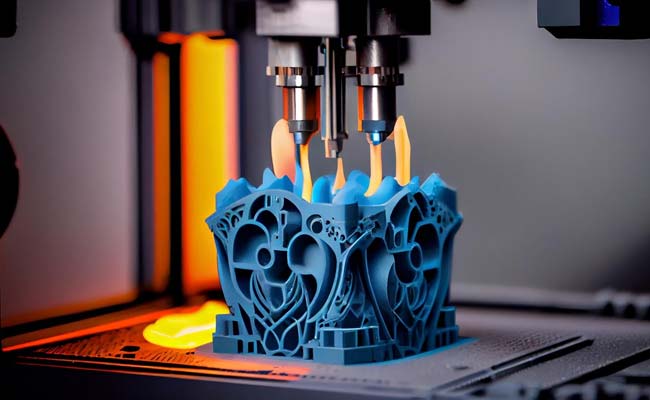

● High-precision processing to ensure welding quality

Non-standard welding tools have extremely high processing accuracy and can achieve precise processing of welding materials. Whether it is the control of the shape, size or welding depth of the welding point, extremely high precision requirements can be achieved to ensure the quality and consistency of the welded joint. This high-precision processing feature makes non-standard welding tools have broad application prospects in precision welding, high-quality welding and other fields.

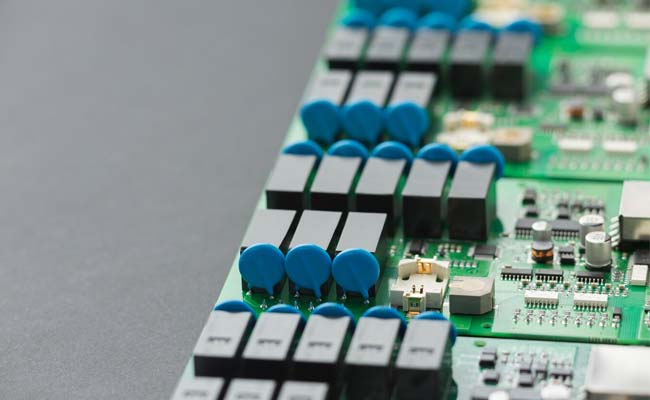

● Strong durability and reduced maintenance costs

Non-standard welding tools use high-quality materials and advanced manufacturing processes to provide excellent durability and stability. In long-term, high-load welding operations, the cutting tools can maintain stable cutting performance and welding quality, and are not prone to wear and damage. This reduces the frequency of tool changes and maintenance costs, saving customers a lot of time and money.

● High flexibility and adaptability

Non-standard welding tools are highly flexible and adaptable and can be adjusted and optimized according to customers' specific needs and changes in welding processes. Whether it is the structural design of the tool or the adjustment of the welding parameters, they can be flexibly adjusted according to the actual situation to adapt to different welding needs and process requirements. This flexibility allows non-standard welding tools to perform optimally in complex and changeable welding environments.

lubin@china-end-mill.com

lubin@china-end-mill.com