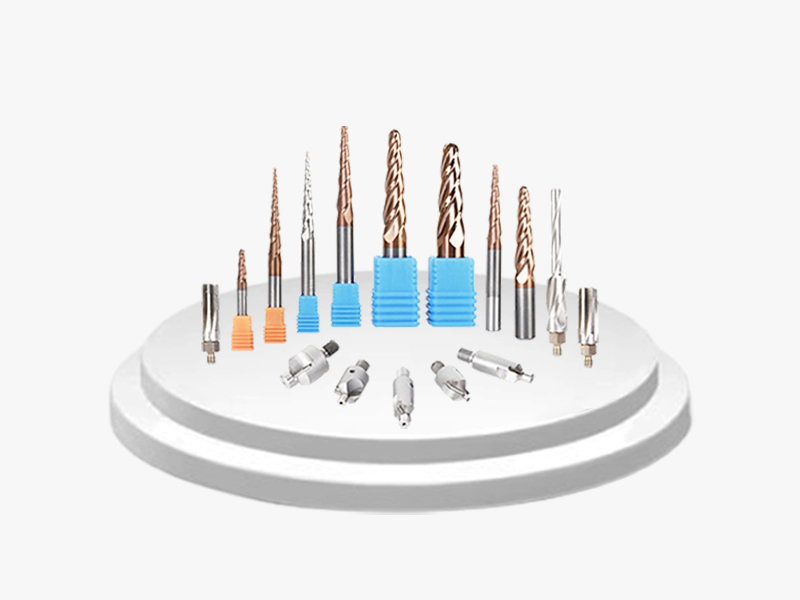

Raw materials: Optional - imported wear-resistant carbide, fine grain tungsten steel

Coating: Optional - TiAlN coating, titanium nitride coating, etc.

Applicable processing materials: optional - stainless steel, aluminum alloy, high temperature alloy, copper and other materials

Processing cooling conditions: optional - spray cooling, air cooling, liquid cooling, dry processing

Features: good rigidity, high wear resistance, high processing precision, short delivery time, a non-standard drill bit saves time and reduces costs

lubin@china-end-mill.com

lubin@china-end-mill.com