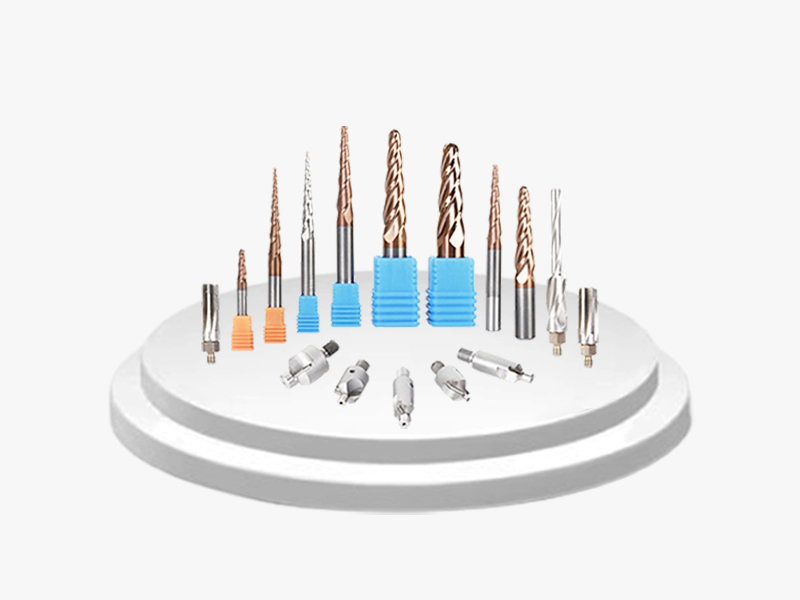

Drill reamer, as an efficient cutting tool, has a wide range of applications in the field of mechanical processing. It combines the functions of drilling and reaming, and can complete the drilling and finishing processes in one go, greatly improving processing efficiency.

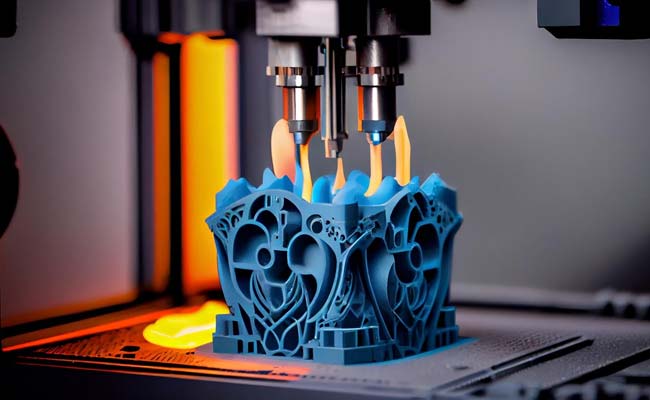

This tool is mainly used to make holes in sandwich composite materials such as carbon fiber materials and graphite. The unique drill and reamer integrated design allows the drill and reamer to be formed in one go, which can effectively prevent the workpiece from burrs, delamination and peeling. The hole has a high finish and is suitable for pneumatic and Hand tool machining.

The drill reamer is made of high-quality materials and undergoes a precise heat treatment process to ensure the hardness and toughness of the tool and its ability to withstand high-load cutting work. Its unique cutting edge design makes the cutting process smoother, reduces cutting force and cutting temperature, thereby reducing workpiece deformation and tool wear.

This drill reamer offers excellent machining accuracy and stability. Whether in the drilling stage or the reaming stage, it can maintain high-precision cutting, so that the processed hole diameter and surface roughness meet strict requirements. At the same time, the drill reamer also has high rigidity, which can maintain a stable cutting state during the machining process and avoid machining errors caused by vibration.

In addition, drill reamers also have good versatility and flexibility. It is suitable for processing a variety of materials, including metals, non-metals, etc., and can meet the processing needs of different industries. At the same time, the drill reamer can also be customized according to specific processing needs to meet the special requirements of customers.

The drill reamer is an efficient, high-precision, and stable cutting tool that can bring higher processing efficiency and better processing quality to the field of mechanical processing. Choosing a drill reamer will bring higher benefits to your processing and production.

lubin@china-end-mill.com

lubin@china-end-mill.com