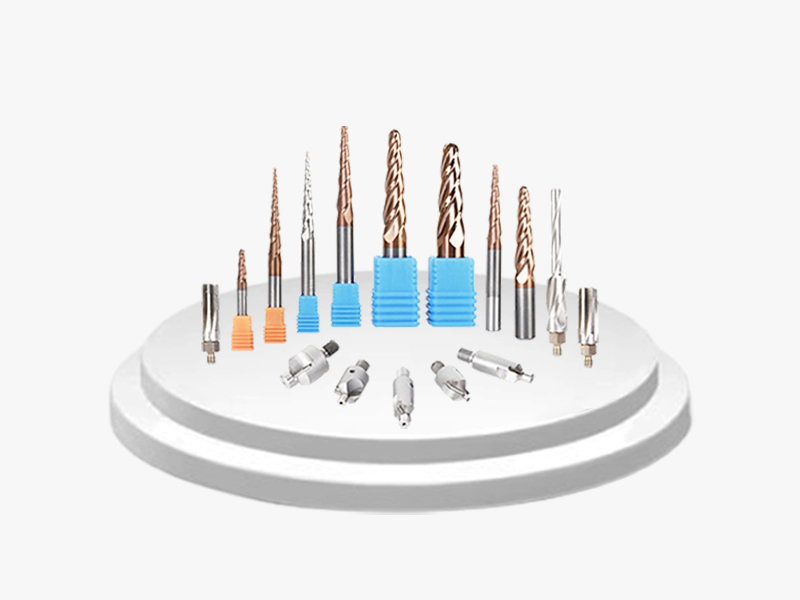

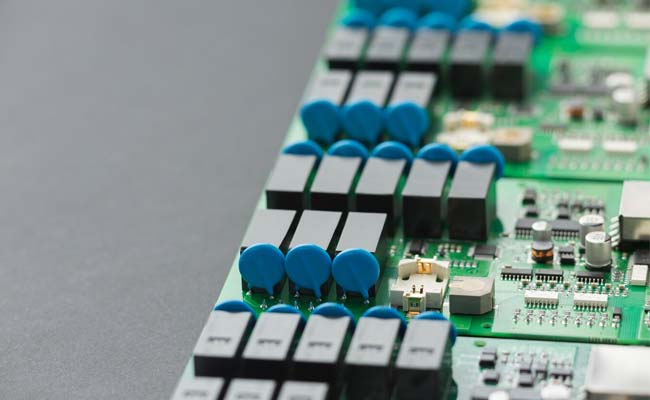

● High accuracy:

Non-standard milling cutters strictly follow high-precision standards during the design and manufacturing process to ensure precise control of size and shape during cutting. This gives non-standard milling cutters significant advantages in the field of complex curved surfaces and fine machining, and can achieve high-precision machining requirements.

● Efficient cutting performance:

Non-standard milling cutters use advanced materials and optimized designs, giving them excellent cutting performance and stability. During the machining process, non-standard milling cutters can reduce vibration and heat generation, improve cutting efficiency, and reduce energy consumption, thereby helping customers improve production efficiency.

● Wide applicability:

Non-standard milling cutters can be customized for various materials and processing needs, and are suitable for processing metal, wood, plastic and other materials. Whether it is flat, curved or special-shaped parts, non-standard milling cutters can provide excellent processing results and meet the application needs of different industries and scenarios.

● Strong durability:

Non-standard milling cutters use high-quality materials and precision processes during the manufacturing process to ensure high durability and service life. With correct use and maintenance, non-standard milling cutters can maintain long-term cutting performance, reduce replacement frequency, and reduce production costs.

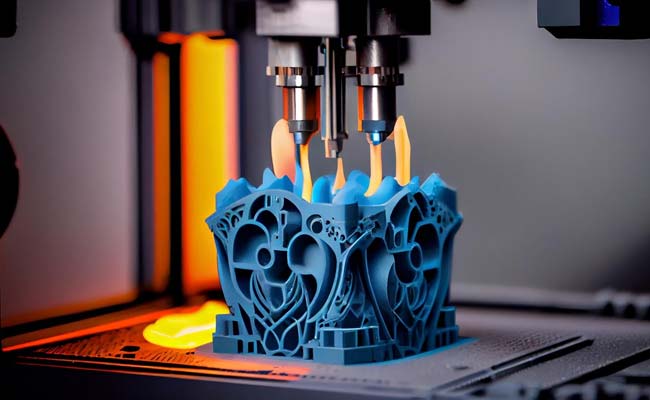

● Personalized customization service:

Non-standard milling cutters provide personalized customization services and can be customized according to customers' specific needs and processing conditions. This flexibility allows non-standard milling cutters to better adapt to various complex machining tasks and meet customer-specific machining needs.

lubin@china-end-mill.com

lubin@china-end-mill.com