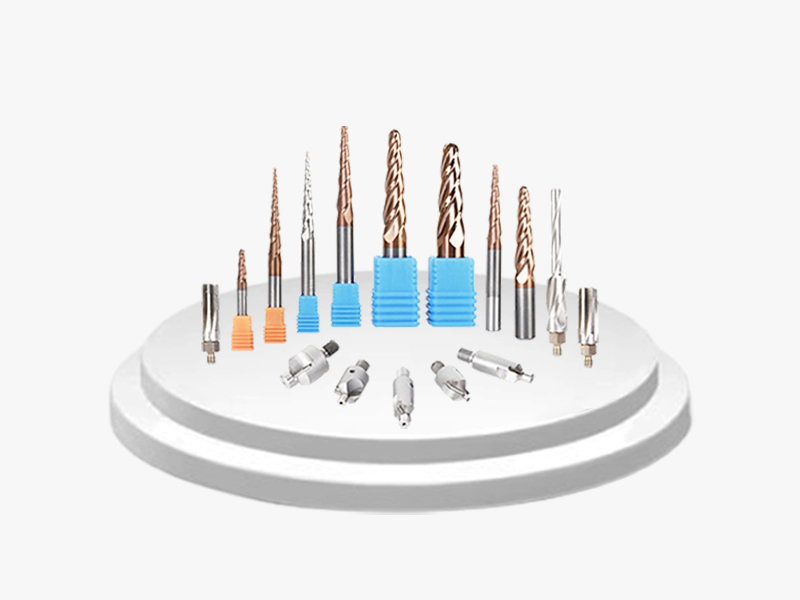

The straight shank drill bit is a professional cutting tool used for drilling operations. Its unique straight shank design makes the operation more convenient while ensuring the stability and efficiency of processing. With its excellent performance and wide applicability, this product is favored by the majority of users in the field of mechanical processing.

The straight shank drill bit is made of high-quality materials and undergoes precise machining and heat treatment to ensure the tool's durability and excellent cutting performance. Its cutting part is designed with a special geometry that can penetrate the workpiece quickly and accurately to achieve high-quality drilling operations. Whether it is metal, non-metal or composite materials, the straight shank drill bit can easily handle it, showing its powerful processing capabilities.

The straight shank design is a highlight of this drill. This design makes the connection between the drill bit and the machine tool simpler and more direct, making it convenient for users to install and replace. At the same time, the straight shank structure enhances the overall rigidity of the drill bit, effectively reduces vibration and deviation during processing, and improves processing stability. This stability ensures that the drill bit can maintain a stable cutting state when rotating at high speed, improving the accuracy and efficiency of drilling.

In addition, straight shank drill bits have excellent heat dissipation properties. During high-speed rotation and cutting, the drill bit can effectively reduce heat accumulation and reduce tool wear, thereby extending service life. Users do not need to replace drill bits frequently, which reduces production and maintenance costs.

The straight shank drill bit is a cutting tool that combines high precision, stability, and durability. It can meet various drilling needs and is widely used in machinery manufacturing, automobile maintenance, aerospace and other fields. Whether it is mass production or precision machining, straight shank drill bits can exert their excellent performance and advantages to help users achieve high-quality drilling operations. Whether you are a beginner or a professional technician, you can easily get started and get the best out of it.

lubin@china-end-mill.com

lubin@china-end-mill.com