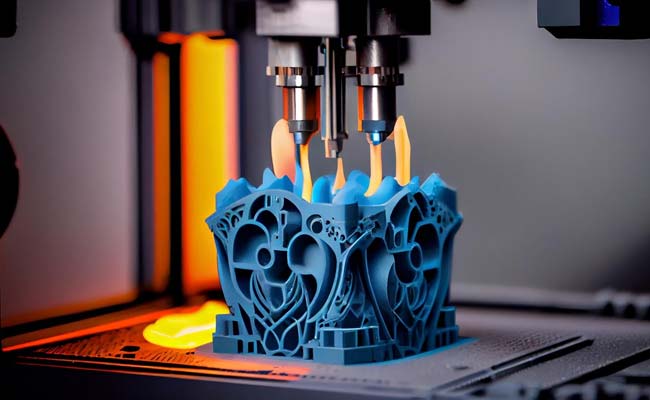

● Efficient cutting

Single-edged milling cutters are uniquely designed. Their single cutting edge concentrates cutting force, allowing them to quickly penetrate the workpiece and remove material efficiently. This design reduces energy loss during the cutting process, improves cutting efficiency, and makes the processing process faster.

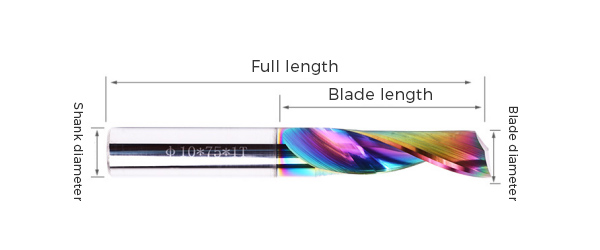

● High-precision processing

Single-edged milling cutters undergo strict quality control during the manufacturing process to ensure the accuracy and stability of their cutting edges. This enables the single-edge milling cutter to maintain stable cutting depth and direction during the machining process, achieving high-precision machining requirements. Whether it is a flat surface, a curved surface or a complex shape, it can be easily handled and the processing quality is guaranteed.

● Excellent wear resistance

The single-edge milling cutter is made of high-quality materials and undergoes a special heat treatment process to give it excellent wear resistance. In the long-term cutting process, the cutting edge is not easy to wear and can maintain a long service life. This reduces the frequency of tool replacement, improves production efficiency, and also saves costs for users.

● Easy to operate

The installation and adjustment of single-edge milling cutters are relatively simple, and users can quickly change tools and adjust parameters according to processing needs. In addition, its good balance and stable operation reduce the difficulty of operation, making it easy for even beginners to get started.

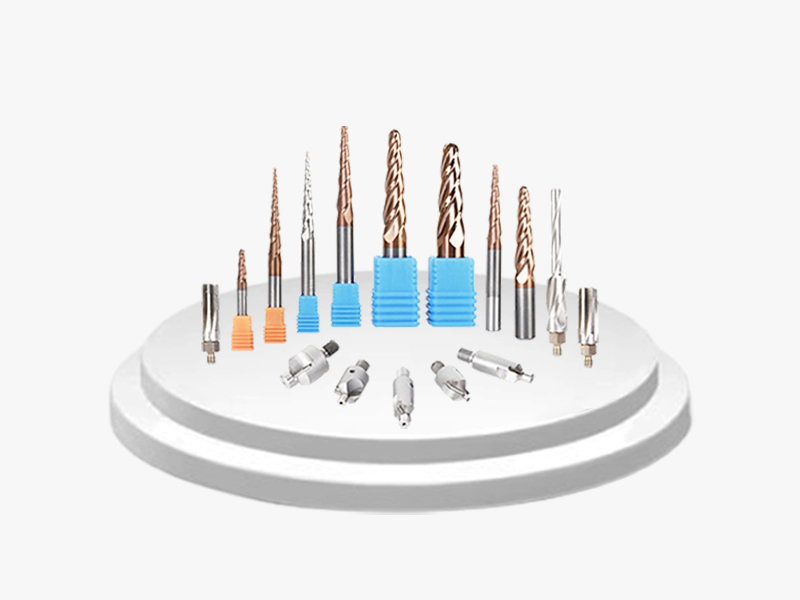

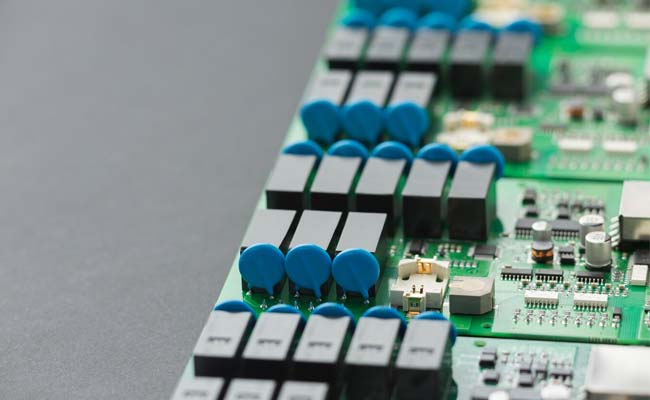

● Wide applicability

Single-edge milling cutters are suitable for processing a variety of materials, including metals, non-metals, etc. Whether it is harder materials or more fragile materials, single-edge milling cutters can demonstrate good cutting performance. This makes it widely used in aerospace, automobile manufacturing, mold processing and other fields.

SUITABLE FOR PROCESSING MATERIALS

lubin@china-end-mill.com

lubin@china-end-mill.com