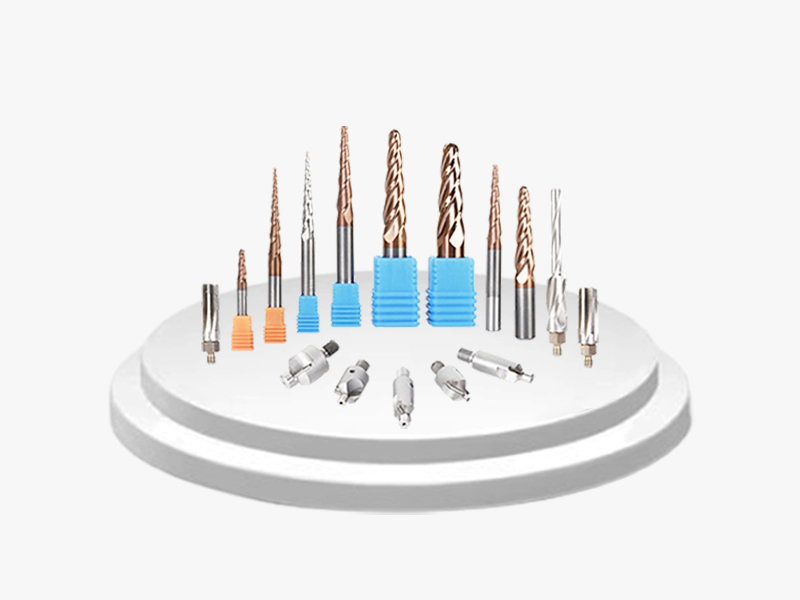

● Efficient cutting performance:

The steel milling cutter is optimized for the cutting characteristics of steel. Its sharp cutting edge and reasonable geometric structure make the cutting process more efficient. It can quickly cut into materials, reduce cutting force, and increase cutting speed, thereby significantly shortening the processing cycle and improving production efficiency.

● High hardness and wear resistance:

Steel milling cutters are made of high-hardness materials, such as carbide or high-speed steel, and undergo a special heat treatment process to make them hard and wear-resistant. This ensures that in long-term, high-load cutting operations, steel milling cutters can maintain stable cutting performance, are not prone to wear, and extend service life.

● Excellent thermal stability:

Steel easily generates high heat during the cutting process, and steel milling cutters have good thermal stability. It can withstand high temperatures without deforming or losing cutting performance, ensuring stable cutting results in high temperature environments.

● Precise cutting accuracy:

Steel milling cutters undergo precision manufacturing and strict quality control to ensure the stability and reliability of their cutting accuracy. It can achieve high-precision cutting processing, meet the processing needs of complex workpieces and high-precision parts, and improve product quality and consistency.

● Good versatility and adaptability:

Milling cutters for steel come in a variety of specifications and models, which can be adapted to the processing needs of different steel materials. Whether it is roughing or finishing, whether it is plane milling or contour milling, steel milling cutters can provide reliable cutting solutions to meet the needs of various processing scenarios.

SUITABLE FOR PROCESSING

lubin@china-end-mill.com

lubin@china-end-mill.com