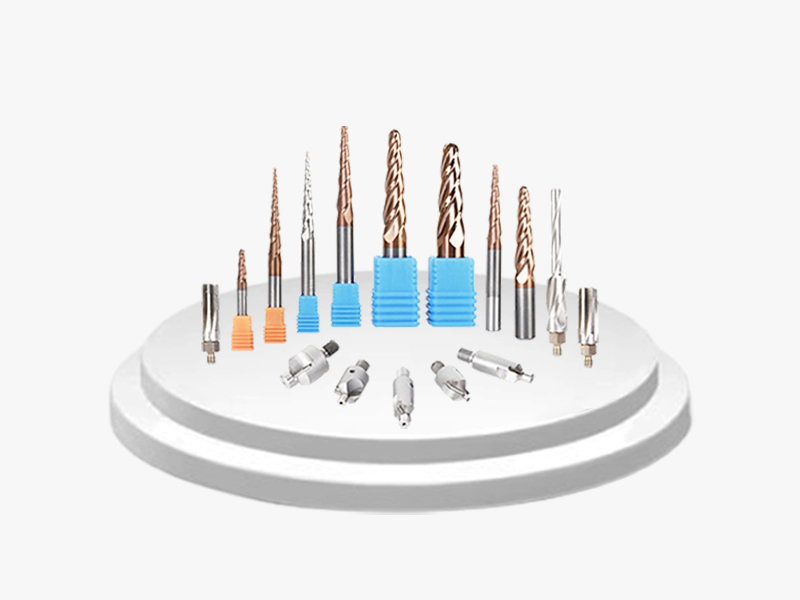

Interchangeable Cutter Head Assembly Tool

Interchangeable Cutter Head Assembly Tool

Standard Tools

Standard Tools

Single edge milling cutter

Milling cutter for aluminum

50° milling cutter for bronze steel

60° milling cutter for black steel

Carbon fiber milling cutter

55° Purple Steel Milling Cutter

Small diameter milling cutter

Milling cutter for 65° blue steel

Wave edge rough and fine integrated milling cutter

Large helix angle milling cutter

Aluminum drill bit

Drill bits for steel

Non-standard Tools

Aviation Cutting Tools

lubin@china-end-mill.com

lubin@china-end-mill.com